ADRES Supervisory Control and Data Acquisition (SCADA) Controls Product Summary

Deploy a cost effective Wireless ADRES SCADA controller with configurable Modbus interface for control, monitoring, trending and alarming of remotely located assets, systems and devices

A bit about the ADRES wireless Supervisory Control and Data Acquisition (SCADA) solution for your remotely located assets, systems and devices

Deploy a cyber secure wireless SCADA controller to monitor, control, trend, maintain and alarm your remotely located hard to reach assets, equipment and systems. Receive alarm notification each time the asset is off-line, in standby, running, or in an alarm condition. Ideal for smart grid applications including the following:

- Diesel or Natural Gas Generators

- Solar PV Systems with or without Battery Energy Storage

- Wind Turbines

- Vehicle Charge Stations

- Waste Water Lift Stations

- Water Pumping Stations

- Cellular Repeater Sites

- Utility Protection Systems including Reclosers and Substation

- Process Systems and Equipment

- Traffic Signals and Controls

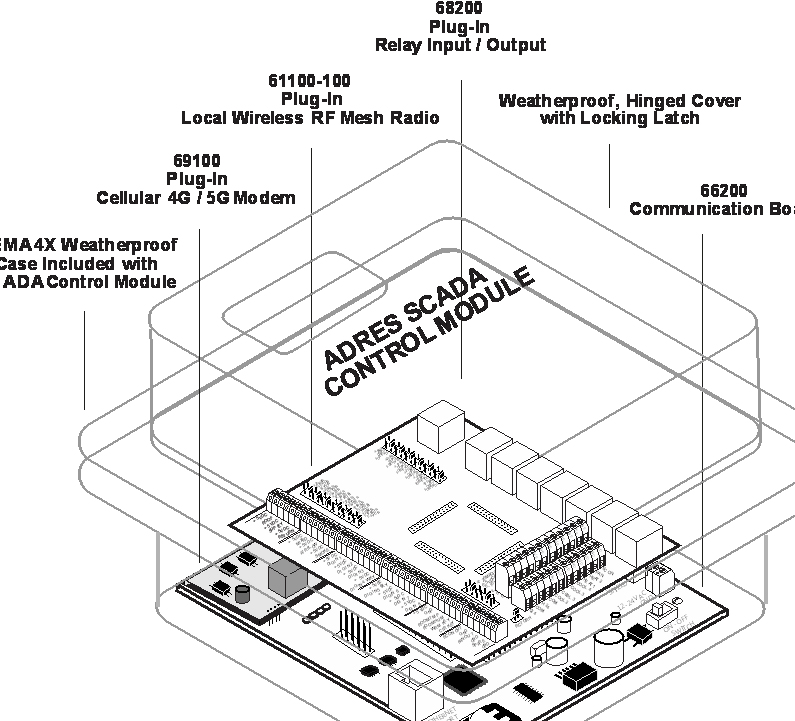

The ADRES control solution comes in a NEMA 4X weatherproof enclosure and is a bolt-on controller that can either communicate through its configurable Modbus serial and or Ethernet communication ports to any Modbus TCP/IP or Modbus serial RTU end device. If the assets or system does not support communication, the ADRES controller has a plug-in expansion board allowing for analog inputs, digital inputs and outputs as well as form C relay outputs to connect to monitor and control the asset or system. Below is an overview of an ADRES SCADA controller with plug in Cellular 4G / 5G modem.

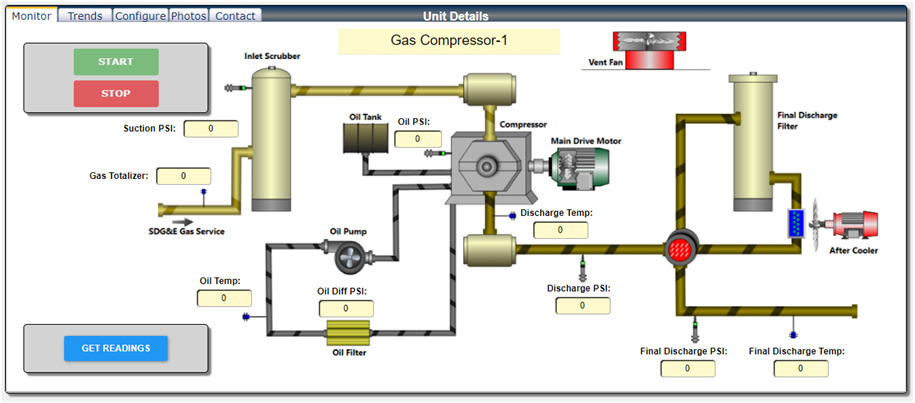

Configure the ADRES controller in the ADRESpro web based Human Machine Interface (HMI). Setup one or many end customers, one or many end customer buildings, facilities, assets, or systems and setup any number of ADRES controller within each location.

If configuring the ADRES controller for Modbus TCP/IP Ethernet and or Modbus Serial RS-485 communication, use the Modbus Profile configurator and testing pages in the ADRESpro HMI to read or write the Modbus registers desired for the end device or system.

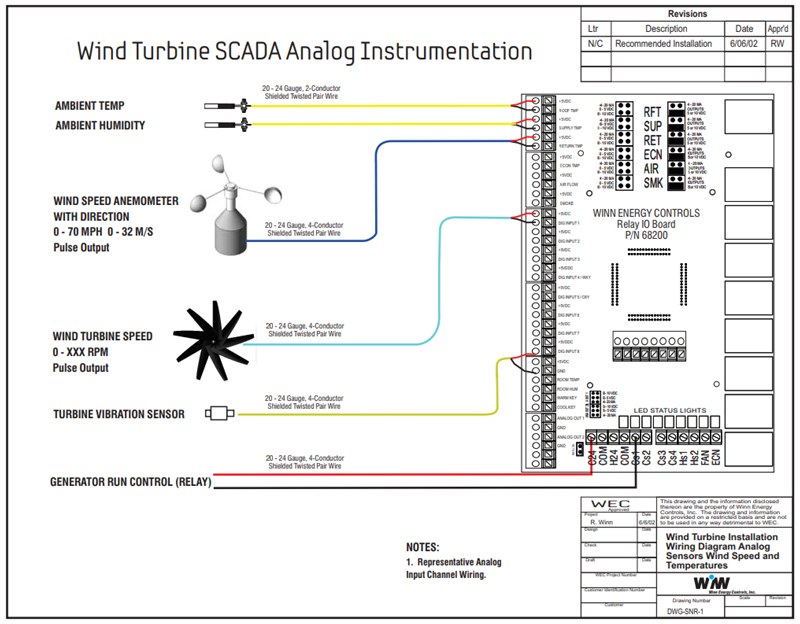

If the end device or system does not support Modbus communication, or if additional sensor, instrumentation or control functions are required, install the optional relay I/O board. The Relay I/O board has eight form C pilot relays, eight analog inputs, jumper selectable for (0-5 VDC, 0-10 VDC or 4/20 ma) signals, eight digital inputs, eight digital outputs, and two analog outputs, jumper configurable for (0-5 VDC, 0-10 VDC or 4/20 ma). The ADRESpro HMI has setup and configuration pages for each type of channel and each individual channel to correctly configure for analog, digital inputs, outputs or relays

The ADRES control is also compatible with many electric, gas and water submeter systems with either Modbus communication, or dry contact pulse outputs.

Custom HMI monitoring screens can be built for recurring end devices and systems.

The ADRESpro HMI is available to end customers, contractors, utilities, and developers to access all the systems’s performance, trend, alarms, reports in a customer’s fleet through the Internet via either PC, tablet or smart phone. The ADRESpro Mobile is the smart phone or table application to view alarms and warnings or maintenance and service work orders, through email and text messages.

In addition to typical alarms and warning notifications being sent to facility, engineering and contractor personnel, the ADRESpro can be used to send notifications of Demand Response actions being performed by the ADRES system for utility requested load shed or curtailment. Notification can be sent prior to the outage or load shed being executed and additional Notification can be sent when the outage or curtailment is completed.

ADRESpro provides a complete Operations and Maintenance tracking capability to record preventative, corrective or unscheduled maintenance activities. ADRESpro supports adding digital images of before and after of the construction or maintenance activities to document all work performed. Tracking of all parts and material used in the maintenance activity is also provided.

ADRESpro has the capability to allow facility management the ability to dispatch companies or individuals to perform support work including commodity supply vendors, end device or system contractor preventative and corrective maintenance work. ADRESpro tracks the progress and completion of each work order.

ADRESpro HMI also has several pre-configured reports including

- Engine / Generator emissions reporting capability meeting most state environmental protection agency air pollution control district (APCD) permit and reporting requirements.

- Measurement and Verification (M&V) of upgraded or retrofitted equipment or systems applying for utility rebate and incentives or simply operating under a shared savings or guaranteed savings agreement.

- Preventative and corrective maintenance real-time tracking and documenting system complete with parts used, material and commodity used, before and after digital images of work performed.

One or many ADRES controllers with preconfigured and testing firmware can be added to provide full control over:

- Diesel or Natural Gas Generators

- Solar PV with Battery Storage

- Vehicle Charge Stations

- Lift Stations

- Pump Jacks

- Wind Turbines

- Solar Thermal Systems

- Utility Reclosers

- Lighting Systems

- HVAC systems

- Air Handlers

- Boilers

- Chillers

- Refrigeration Systems

- VAV boxes